3.5 years of daily index card comics; The Informalities, they continue.

I’ve spent more time with pink spray paint and packing materials than I ever thought possible which probably explains why I decided this post was worth the time it took to post it.

metalwork forever homes

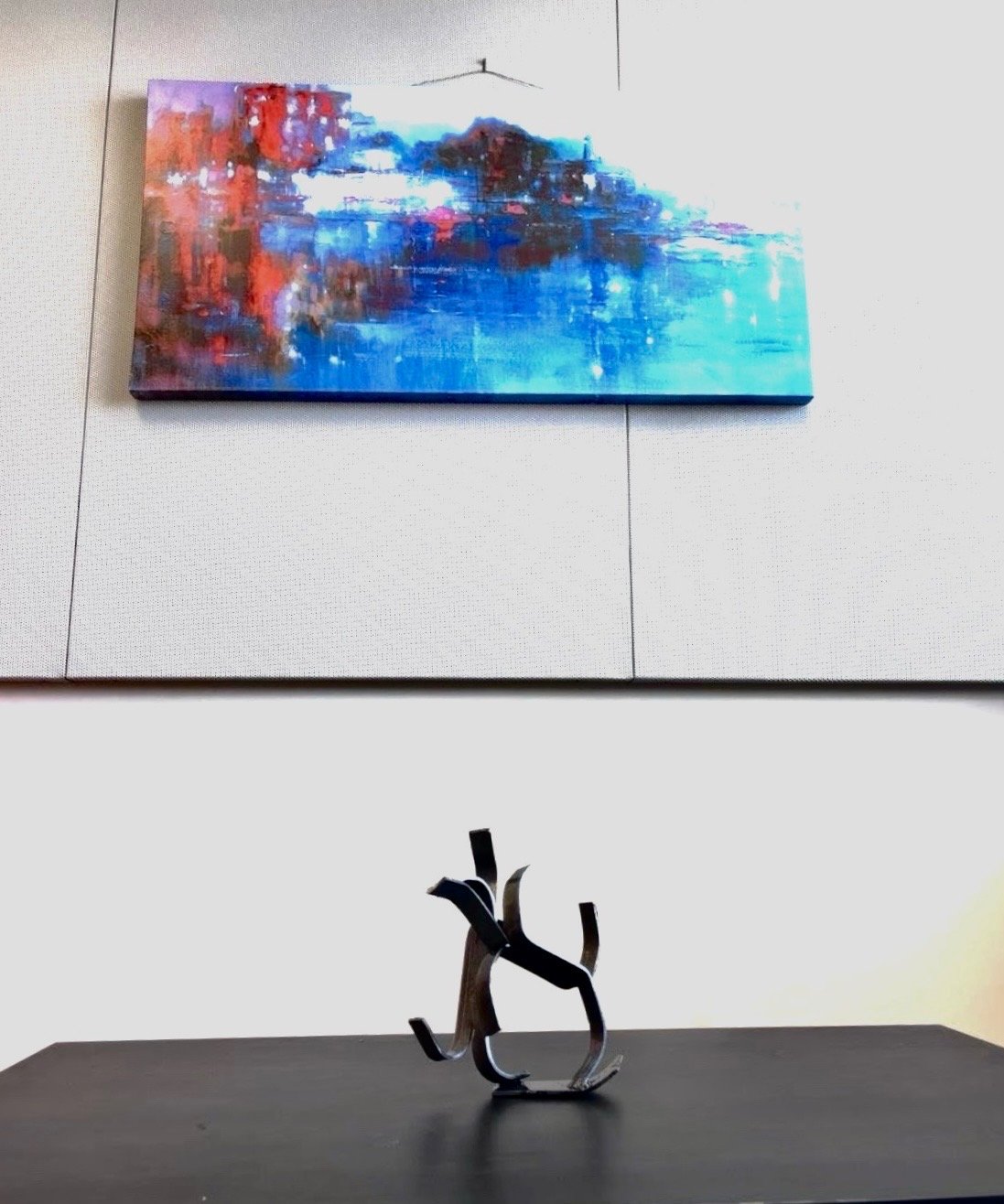

A day of metalwork pieces landing in their forever homes. First, metal_0081 made it to Los Angeles:

And Kirby and I just got back from taking metal_0086, Chernabog, to his new home at my favorite tattoo parlor, Painted Ivy.

He behaved in his car seat.

metal_0089 :: phone stand 03 (flatrod 08)

Wanted to do this one along with 0087 and 0088 yesterday but ran out of what limited brain power I have.

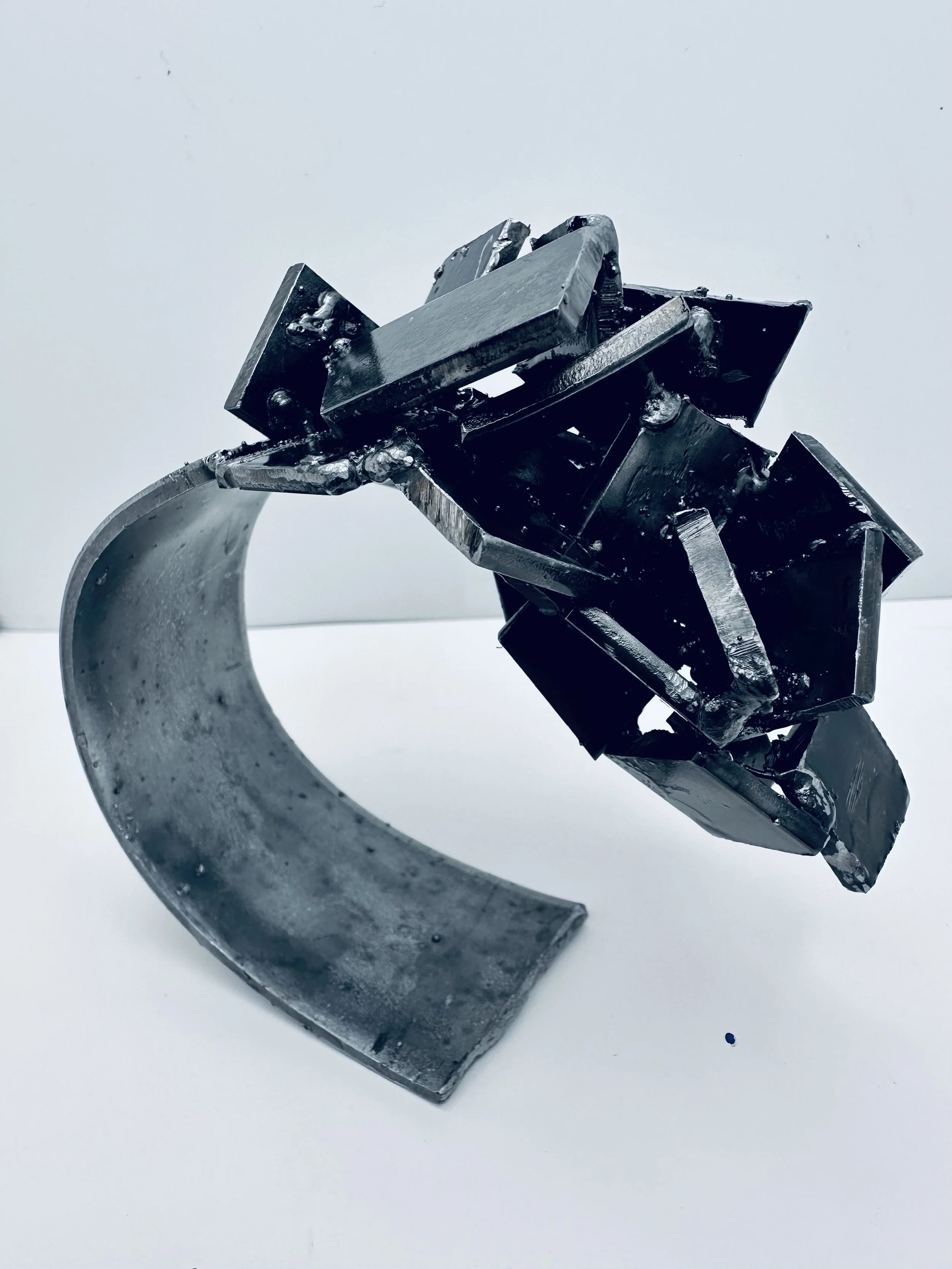

metal_0086 :: chernabog

First warm weather of the year, first big(ger) piece of the year. FANTASIA's one of my favorites, and "Night on Bald Mountain" is, as The Beatles once said, "the toppermost of the poppermost."

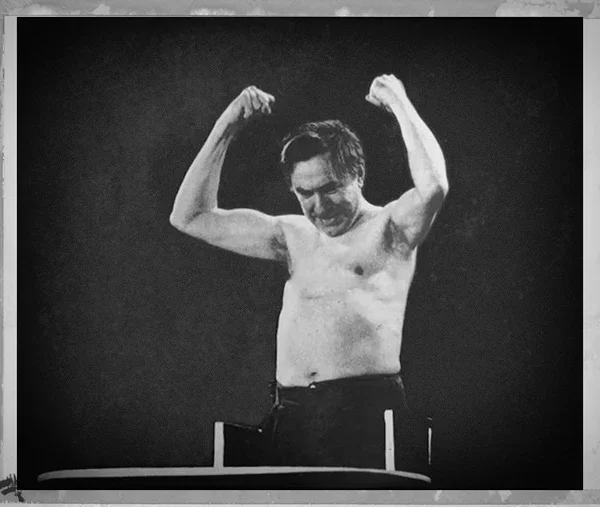

And here’s a fantastic shot of Bela Lugosi providing Chernabog reference for Disney animators:

And, Chernabog in his new forever home, Painted Ivy Tattoo.