metal_0089 :: phone stand 03 (flatrod 08)

Wanted to do this one along with 0087 and 0088 yesterday but ran out of what limited brain power I have.

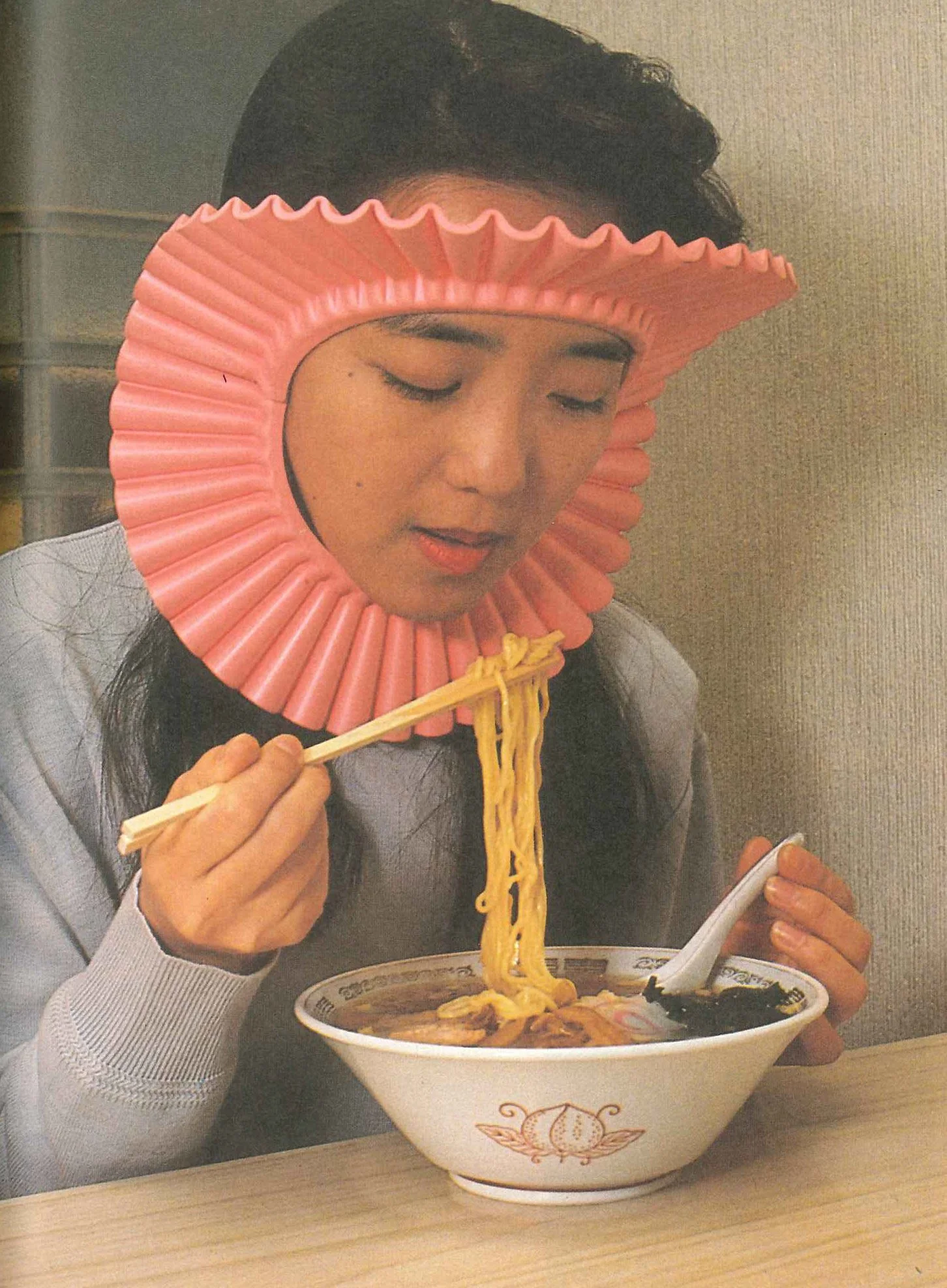

“un-useless”

“Chindogu are inventions that defy concise explanation. They aren't useful. But they aren't completely useless either. Their creator, Kenji Kawakami, describes them as "un-useless." - Chindogu: The Unuseless inventions of Kenji Kawakami

Stunning custom guitars: Cindy Guitars // Insta

Japanese Metabolism

via Wallpaper

Metabolism’s genesis as an architectural tool for social change was defined by the times. It was in the 1950s that the seeds of the movement were first planted amid the ashes of Japan’s widespread post-war urban annihilation and subsequent renaissance.

As Japan’s recovery journey gathered pace, a string of young architects in Tokyo – including Kisho Kurokawa, Fumihiko Maki, Kiyonori Kikutake – were deeply drawn to explorations of flexible, modular and organic urban design, with inspiration rooted in biology, technology and futurism.

Soon after, Japan was on the brink of enormous economic growth. A few years later, in 1964, Japan hosted the Tokyo Olympics and launched its first shinkansen bullet trains – a seminal moment that confirmed to the world its reinvention from war-hit nation to global leader. Added to the mix was a rapidly growing population – all combining to create the perfect conditions for questioning how to reorganise a fast-evolving urban society for the future.

At the same time, ideas of renewal and impermanence have also long been timelessly ingrained across traditional Japanese culture – from its Zen Buddhist philosophies and aesthetics to its ritual of rebuilding Ise-Jingu, one of Japan’s most important shrines, every 20 years.